CHIP BREAKERS CYCLE

Training in the UK

First course to English customers held in co-operation with Roland DG (UK) Ltd and our reseller Skillbond

First course to English customers held in co-operation with Roland DG (UK) Ltd and our reseller Skillbond

Workshop: the dental item from scan to milling

On Wednesday June 8th, at the new Remak premises in Milan, Via Grosio 10/10, we will attend to the Workshop: the dental item from scan to milling.

Starting from a model it will be possible to follow the whole process to get the milled item, in 4 main steps: • Scan the item with an Open Technology's scanner • Model the item with the ExocaD's CAD • Tool-path program with Cimsystem's CAM

From 10:00 it's possible to attend to the presentation held by REMAK and the partner companies. It's also possible to set up an appointment, one ot two weeks before, to satisfy specific requests. The workshop's focus will be mainly on practical applications, the presentations will be held during the morning.

For more info:

Change of address!

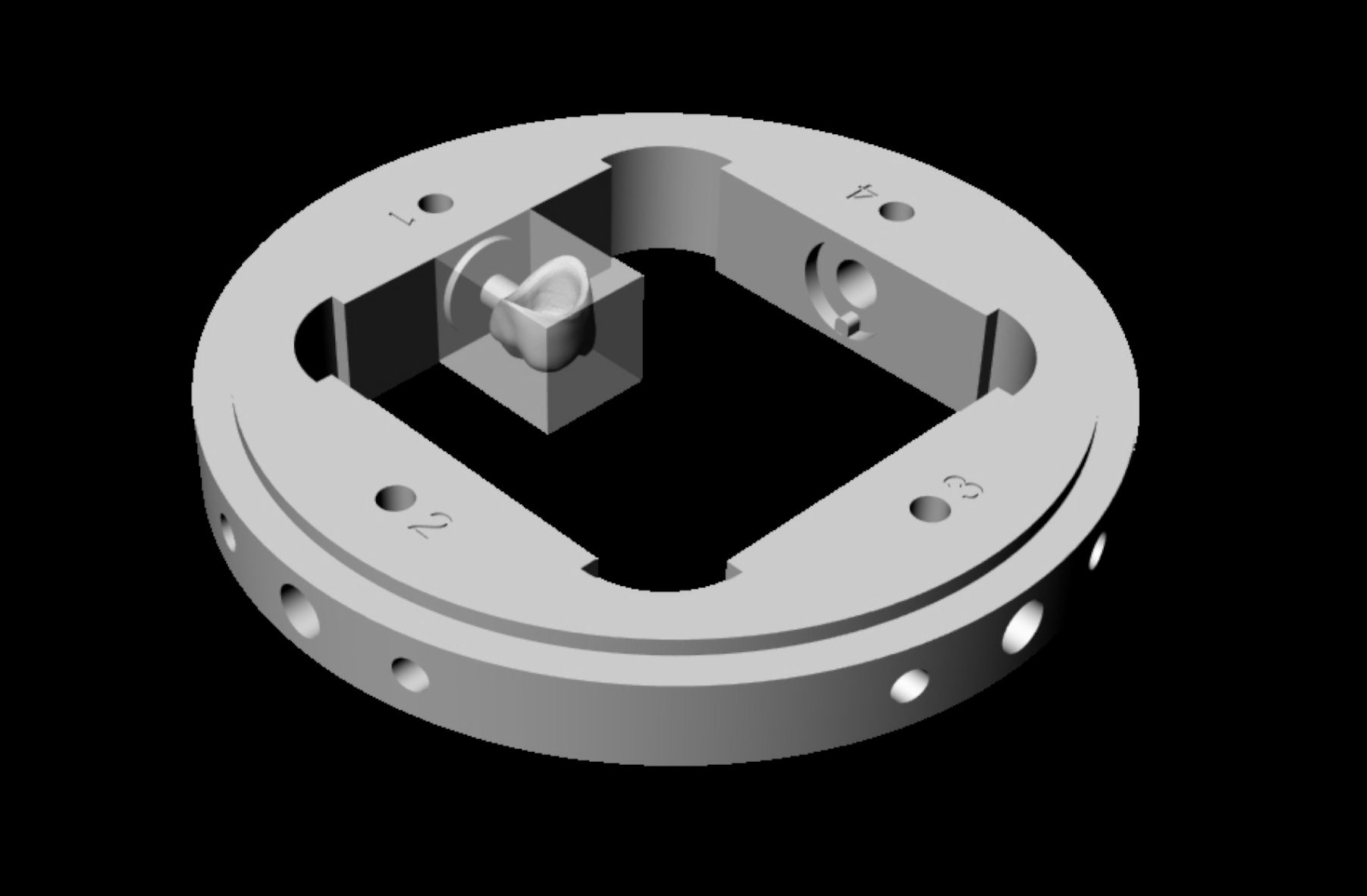

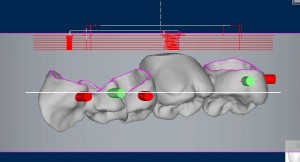

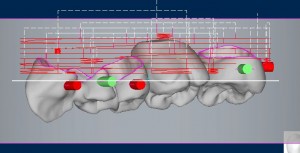

LITHIUM DISILICATE AND CERAMICS

It is now possible to use SUM3D for the grinding of Lithium Disilicate and Ceramics.

Cimsystem has prepared a special kit including:

- metallic structure to hold the blocks,

- tools,

- dedicated machining strategies,

- related training course

The kit has been tested giving excellent results with various customers.

CHANGES IN THE “PORTION” CODE

<PORTION1/2,DEPTH3>

Increment value in Z = 0.5

<PORTION1/2,DEPTH-3>

Increment value in Z = 1

SINO-DENTAL 2012

AMICI DI BRUGG 2012

EUROSTAMPI 2012

IDS 2011

COLLOQUIUM 2010

Expo 2009

Articles:

- CHIP BREAKERS CYCLE

- SUM3D Dental works this way.

- Training in the UK

- Workshop: the dental item from scan to milling

- 5 AXIS IN CONTINUOUS

- Change of address!

- LITHIUM DISILICATE AND CERAMICS

- We wish you health, happiness and success for the New Year!

- SINTERING STABILIZER

- 5 AXIS CONTINUOUSLY

- DIMENSIONAL CHECK

- 4 AXIS IMPLANTS’ MILLING

- POCKETING

- NEW FINISHING METHODS

- STRATEGIES TO DOWNLOAD

- DETECTION OF SINGLE AXES IN BRIDGES

- UNDERCUTS’ OPTIMIZATION

- AMICI DI BRUGG – Rimini, May 27th – 29th, 2010

- TIME’S CALCULATION

- SUM3D DENTAL AT EXPODENTAL MADRID

- EXAMPLE OF IMPLANT’S MACHINING By ESTUDIO PREVIO MADRID

- A NEW SUM3D DENTAL INSTALLATION ON HERMLE

- CREATE RAW

- USING SUM3D DENTAL WITH DATRON

- SUM3D DENTAL VIDEOS

- SUM3D DENTAL

- DENTAL SHAPER

- SUM3D DENTAL STATISTICS

back to home page

back to home page

back to top

back to top