CHIP BREAKERS CYCLE

Training in the UK

First course to English customers held in co-operation with Roland DG (UK) Ltd and our reseller Skillbond

First course to English customers held in co-operation with Roland DG (UK) Ltd and our reseller Skillbond

Workshop: the dental item from scan to milling

On Wednesday June 8th, at the new Remak premises in Milan, Via Grosio 10/10, we will attend to the Workshop: the dental item from scan to milling.

Starting from a model it will be possible to follow the whole process to get the milled item, in 4 main steps: • Scan the item with an Open Technology's scanner • Model the item with the ExocaD's CAD • Tool-path program with Cimsystem's CAM

From 10:00 it's possible to attend to the presentation held by REMAK and the partner companies. It's also possible to set up an appointment, one ot two weeks before, to satisfy specific requests. The workshop's focus will be mainly on practical applications, the presentations will be held during the morning.

For more info:

Change of address!

LITHIUM DISILICATE AND CERAMICS

It is now possible to use SUM3D for the grinding of Lithium Disilicate and Ceramics.

Cimsystem has prepared a special kit including:

- metallic structure to hold the blocks,

- tools,

- dedicated machining strategies,

- related training course

The kit has been tested giving excellent results with various customers.

CHANGES IN THE “PORTION” CODE

<PORTION1/2,DEPTH3>

Increment value in Z = 0.5

<PORTION1/2,DEPTH-3>

Increment value in Z = 1

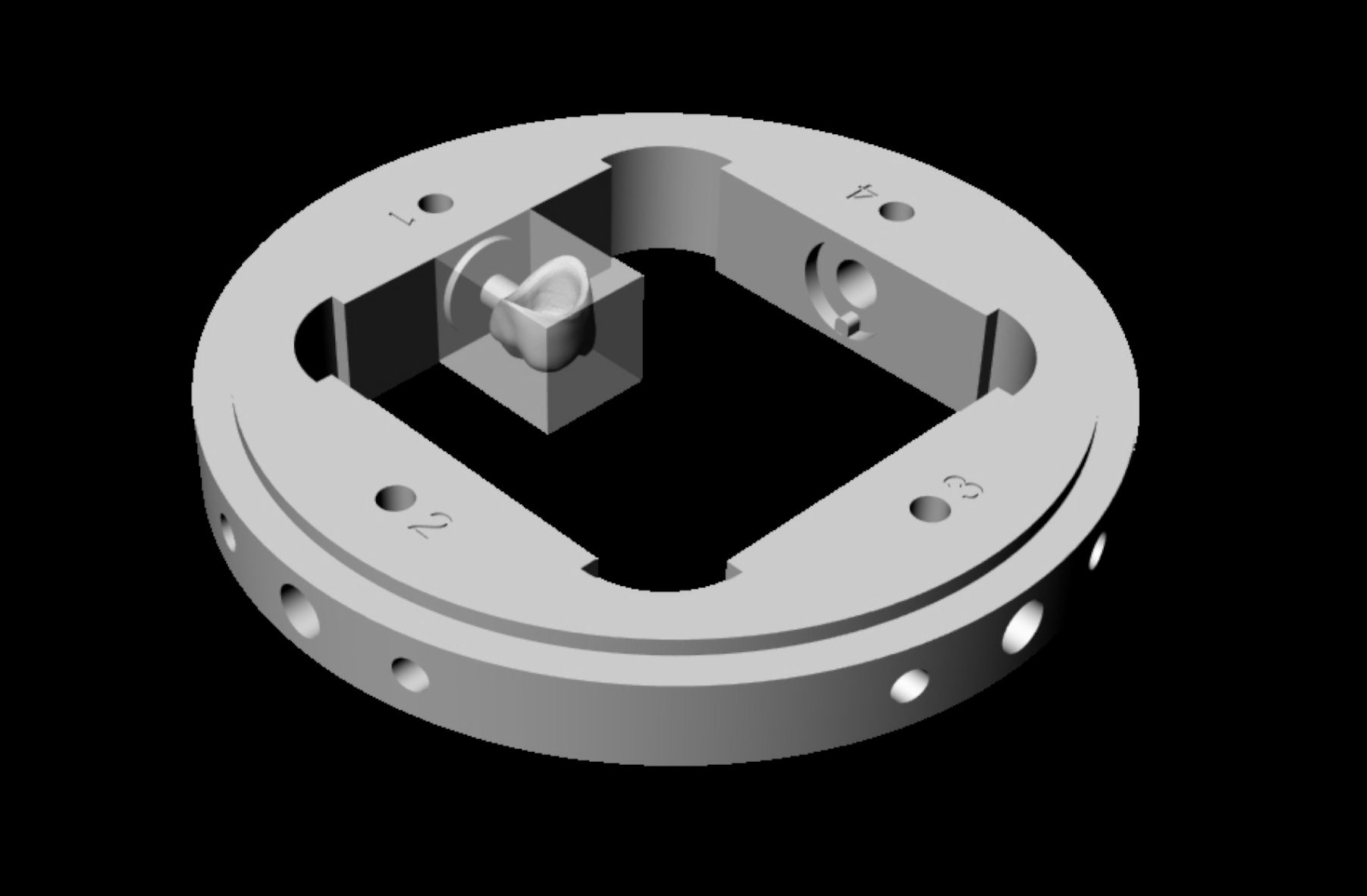

SINTERING STABILIZER

DIMENSIONAL CHECK

VIDEO DEMO

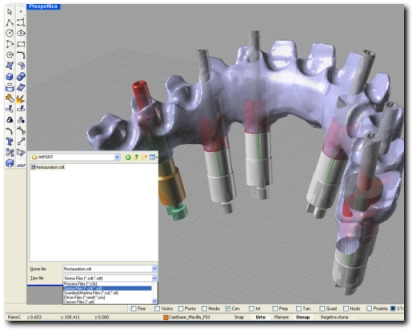

4 AXIS IMPLANTS’ MILLING

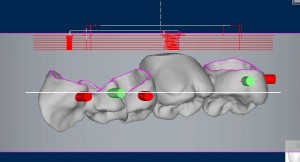

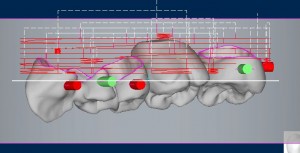

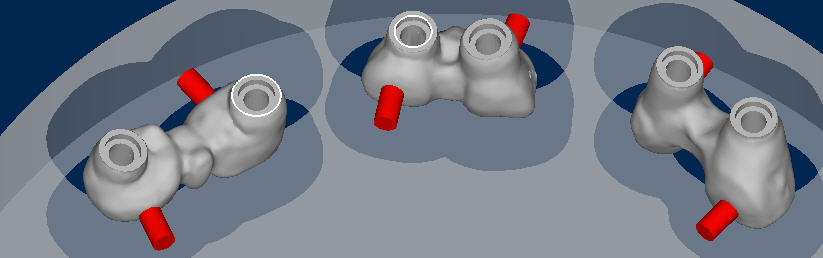

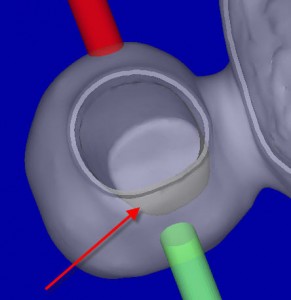

During the import it is now possible to machine automatically 2 holes' implant on 4 axis machines. SUM3D Dental is capable to detect the 2 holes’ implant and the 4 axes machine. A roto-traslation of the implant will be performed to line-up the axes of the 2 holes along the rotation plane of the fourth axis in order to machine the holes by rotating only the fourth axis.

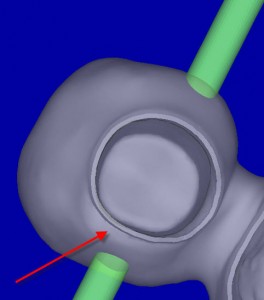

The automatic detection of the axes of the bridges’ cavities allows to eliminate the cavities’ undercuts during the roughing and finishing phases. This important innovation, combined with the use of "lollipop" tools and to the new automatism for the holes' alignment, make of SUM3D Dental an even more formidable tool and an ideal partner also on 4 axes machines.POCKETING

NEW FINISHING METHODS

|

In this picture we set 0.05 for the first 3 mm and 0.2 from 3mm to the end of the cap. Also this Strategy can be downoaded from the website. |

STRATEGIES TO DOWNLOAD

ZIRCONIUM |

|

|

LAST UPDATE 09/06/2010

Strategy for the zirconium machining of a bridge featuring 2 or more non parallel insertion's axes. |

|

|

LAST UPDATE 21/06/2010

Strategy for the zirconium machining of a bridge or single caps featuring internal and external undercuts, re-machined with a Lollipop tool without using 5 axes. |

|

DETECTION OF SINGLE AXES IN BRIDGES

during the import it is calculated the medium axis of the bridge (as published some weeks ago), and now are calculated the insertion axes of each bore of the bridge too. Also the strategies’ management has been modified to allow the roughing and finishing of each cavity and its own axis, removing the undercut during the roughing phase.

during the import it is calculated the medium axis of the bridge (as published some weeks ago), and now are calculated the insertion axes of each bore of the bridge too. Also the strategies’ management has been modified to allow the roughing and finishing of each cavity and its own axis, removing the undercut during the roughing phase.

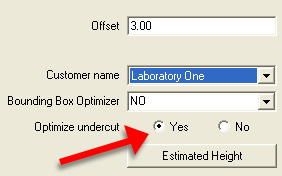

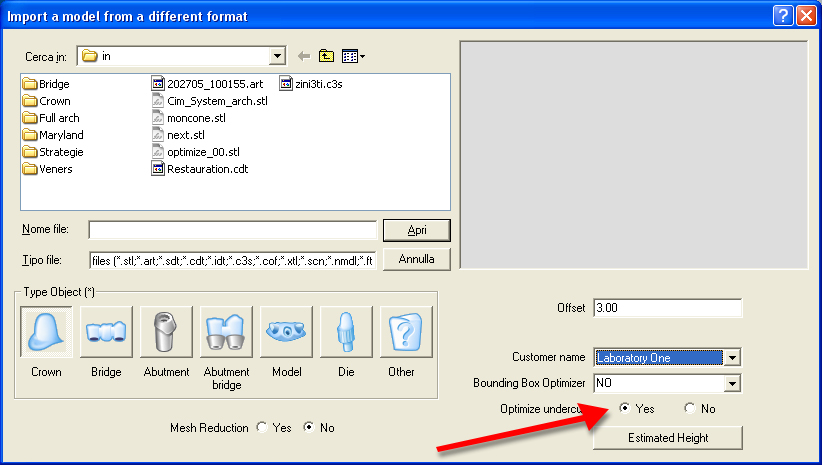

UNDERCUTS’ OPTIMIZATION

AMICI DI BRUGG – Rimini, May 27th – 29th, 2010

Hall : A7 Stand 14

We will present some news:

SUM3D Dental OPTIMIZATION OF THE MACHINING CALCULATION TIME: Now in the time calculation report’s window are also present: Number of tool’s changes, Number of piece’s flips, Time of each tool’s change, Time of each piece’s flip. SUM3D Dental 3 AXES: AUTOMATIC MACHINING OF UNDERCUTS BY USING LOLLIPOP TOOLS Setting the word "SPIRAL" in the strategy's name, the undercut area are automatically detected and managed. The best undercuts' machining can be obtained by using lollipop tools also on 3 axes machines. In case you are using a machine with 3 axes + 1 roatation axis 0/180°, SUM3D Dental can remove the undercuts by using 3/4 of sphere lollipop tools. DENTAL SHAPER CAN ACTUALLY IMPORT: .c3s (Procera™ files) .cdt , .sdt (Sirona™ files) .cof, .xtl (Sweden&Martina™ files) .nmdl, .scn, .ftp (Etkon™ files) .art (Cercon™ files) .dcm (3shape™ files) .box , .cad (Cyrtina™ files) .ccd1 e .ccd2 (3M ESPE Lava™ files) .igs, .iges (KAVO ™ files, open mathematical files) .stl (open stereolithography files) DENTAL SHAPER – SOME FEATURES: Semi-automatic detection of the implant axes and of the coupling plane (abutment-fixture) • Insertion and/or replacement of the implant interfaces • Creation of virtual removable models from a single scan's file (e.g.: direct intra-oral scan, or orthodontic scan, or optical scan of the model by Sirona™ systems) • Fast creation of parametric caps, straigt from the scans of the model and the wax-up • Automatic creation of a machining strategy to make a removable master model, of an implant structure, or of a prosthesis on the stump, with a CNC machine (optional pack) • Direct integration with SUM3D Dental

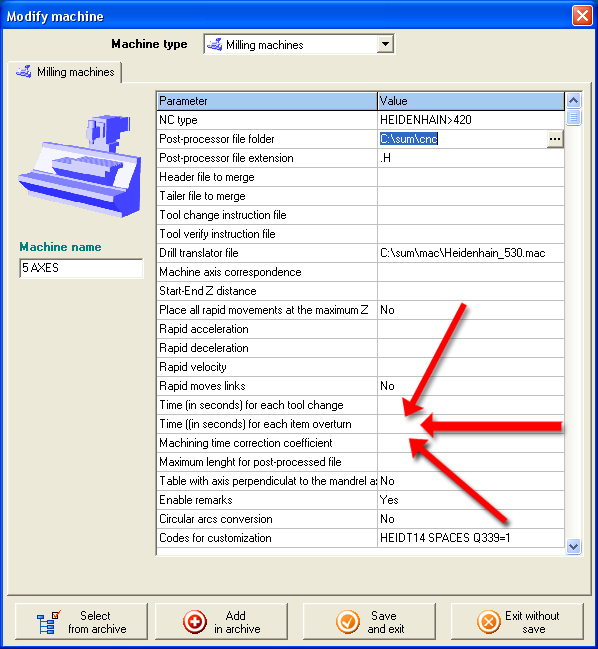

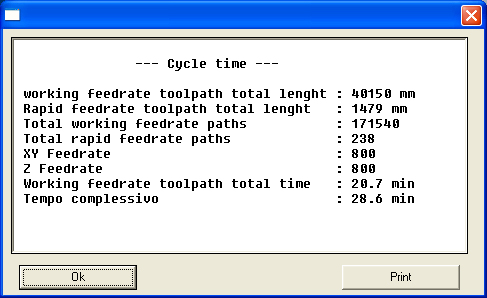

TIME’S CALCULATION

Now in the time calculation report’s window are also present:

Number of tool’s changes, Number of piece’s flips, Time of each tool’s change, Time of each piece’s flip.

Now in the time calculation report’s window are also present:

Number of tool’s changes, Number of piece’s flips, Time of each tool’s change, Time of each piece’s flip.

SUM3D DENTAL AT EXPODENTAL MADRID

CIMsystem will be at Expodental - Madrid from 11th to 13th March 2010 in these halls:

Hall 12 stand 12 A

Hall 12 stand 12 G 05

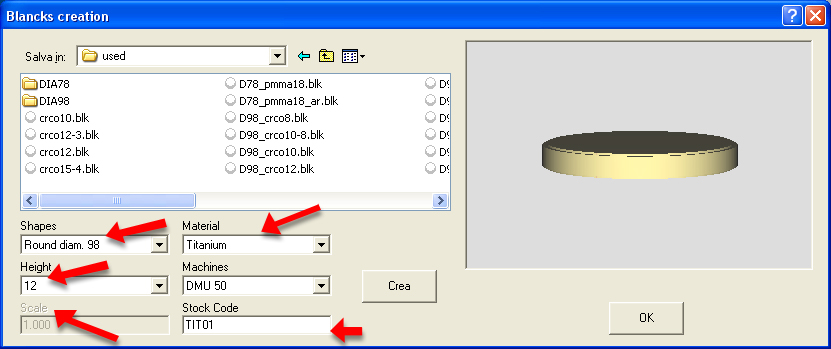

CREATE RAW

In SUM3D Dental new release it has been added a brand new command and the related icon "Create Raw". This command lets you create your own stock library. Starting from standard shapes, like the 98mm disks or from blocks, you can choose the kind of shape, the material, the disk height, the machine you want to use and the stock code. In case you choose the Zirconium material you can set the scaling factor and this will be memorized with the new stock.

In SUM3D Dental new release it has been added a brand new command and the related icon "Create Raw". This command lets you create your own stock library. Starting from standard shapes, like the 98mm disks or from blocks, you can choose the kind of shape, the material, the disk height, the machine you want to use and the stock code. In case you choose the Zirconium material you can set the scaling factor and this will be memorized with the new stock.

USING SUM3D DENTAL WITH DATRON

BY

SUM3D DENTAL

| [ download ] |

|

|

|

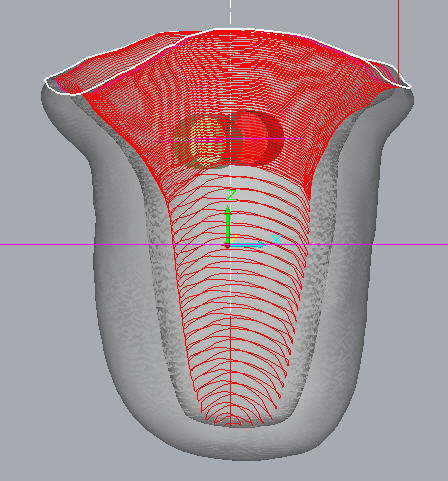

The nesting optimizes the usage of stock material arranging multiple parts in the best position.Support and sintering pins are automatically added to hold the part during the process, their shape, size and position can be easily modified. |

|

The most efficient tool-path and the best machining strategy are automatically generated to fit different materials and tasks. All parameters can be edited. Pre-set strategies and tools are customizable to obtain ad-hoc machining.Undercut areas are automatically detected and managed to be ready for the milling.Accuracy of applied tool-path strategies is ensured by the automatic detection of border-collet and automatic creation of prep-lines. |

All items, tool, spindle, stock and machine parts (including fixtures) are managed to avoid any collision during the machining operation. The simulation displays the tool-path with accurate check of each step of the process, ensuring the good quality of the finished part.The software detects bores and their angles and automatically applies the 5 axes tool-path to realize complete implant bridges and bars.Automatic tool-paths are generated to fit any kind of abutment. |

DENTAL SHAPER

The updated release of Dental Shaper can import CAD files of the following formats:

|

*.c3s |

Procera™ Files |

|

*.cdt - *.sdt - *.idt |

Sirona™ Files |

|

*.cof - *.xtl - *.ftp |

Sweden&Martina™ Files |

|

*.nmdl - *.scn - *.ftp |

Etkon™ Files |

|

*.art |

Cercon™ Files |

|

*.dcm - *.stl |

3shape™ Files |

|

*.box - *.cad |

Cyrtina™ Files |

|

*.ccd1 - *.ccd2 |

Lava (3M) ™ Files |

|

*.stl |

Laserdenta ™ Files |

|

*.stl |

Dentalwings ™ Files |

|

*.stl |

Wieland ™ Files |

|

*.stl |

Evirsa ™ Files |

|

*.stl |

Scansystem ™ Files |

|

*.stl |

OpenTechnology ™ Files |

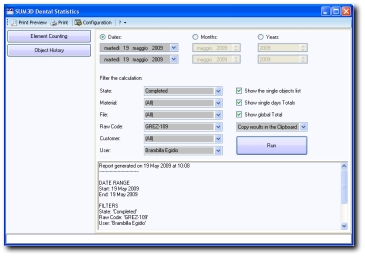

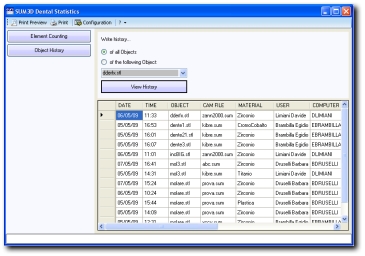

SUM3D DENTAL STATISTICS

| [ download ] |

|

|

SINO-DENTAL 2012

AMICI DI BRUGG 2012

EUROSTAMPI 2012

IDS 2011

COLLOQUIUM 2010

Expo 2009

Articles:

- CHIP BREAKERS CYCLE

- SUM3D Dental works this way.

- Training in the UK

- Workshop: the dental item from scan to milling

- 5 AXIS IN CONTINUOUS

- Change of address!

- LITHIUM DISILICATE AND CERAMICS

- CHANGES IN THE “PORTION” CODE

- We wish you health, happiness and success for the New Year!

- SINTERING STABILIZER

- 5 AXIS CONTINUOUSLY

- DIMENSIONAL CHECK

- 4 AXIS IMPLANTS’ MILLING

- POCKETING

- NEW FINISHING METHODS

- STRATEGIES TO DOWNLOAD

- DETECTION OF SINGLE AXES IN BRIDGES

- UNDERCUTS’ OPTIMIZATION

- AMICI DI BRUGG – Rimini, May 27th – 29th, 2010

- TIME’S CALCULATION

- SUM3D DENTAL AT EXPODENTAL MADRID

- EXAMPLE OF IMPLANT’S MACHINING By ESTUDIO PREVIO MADRID

- A NEW SUM3D DENTAL INSTALLATION ON HERMLE

- CREATE RAW

- USING SUM3D DENTAL WITH DATRON

- SUM3D DENTAL VIDEOS

- SUM3D DENTAL

- DENTAL SHAPER

back to home page

back to home page

back to top

back to top

![IMG_0010[1] IMG_0010[1]](http://www.sum3ddental.com/iblog/wp-content/uploads/2010/02/IMG_00101-300x225.jpg)

![IMG_0011[1] IMG_0011[1]](http://www.sum3ddental.com/iblog/wp-content/uploads/2010/02/IMG_00111-300x225.jpg)